Trif Arrow Press-USA Made

Trif Arrow Press-USA Made

Couldn't load pickup availability

Order numbers 1001-1016 will be shipped by 9/1/25

"Now Available for Pre-Order – Each Unit Will Be Made to Match Demand."

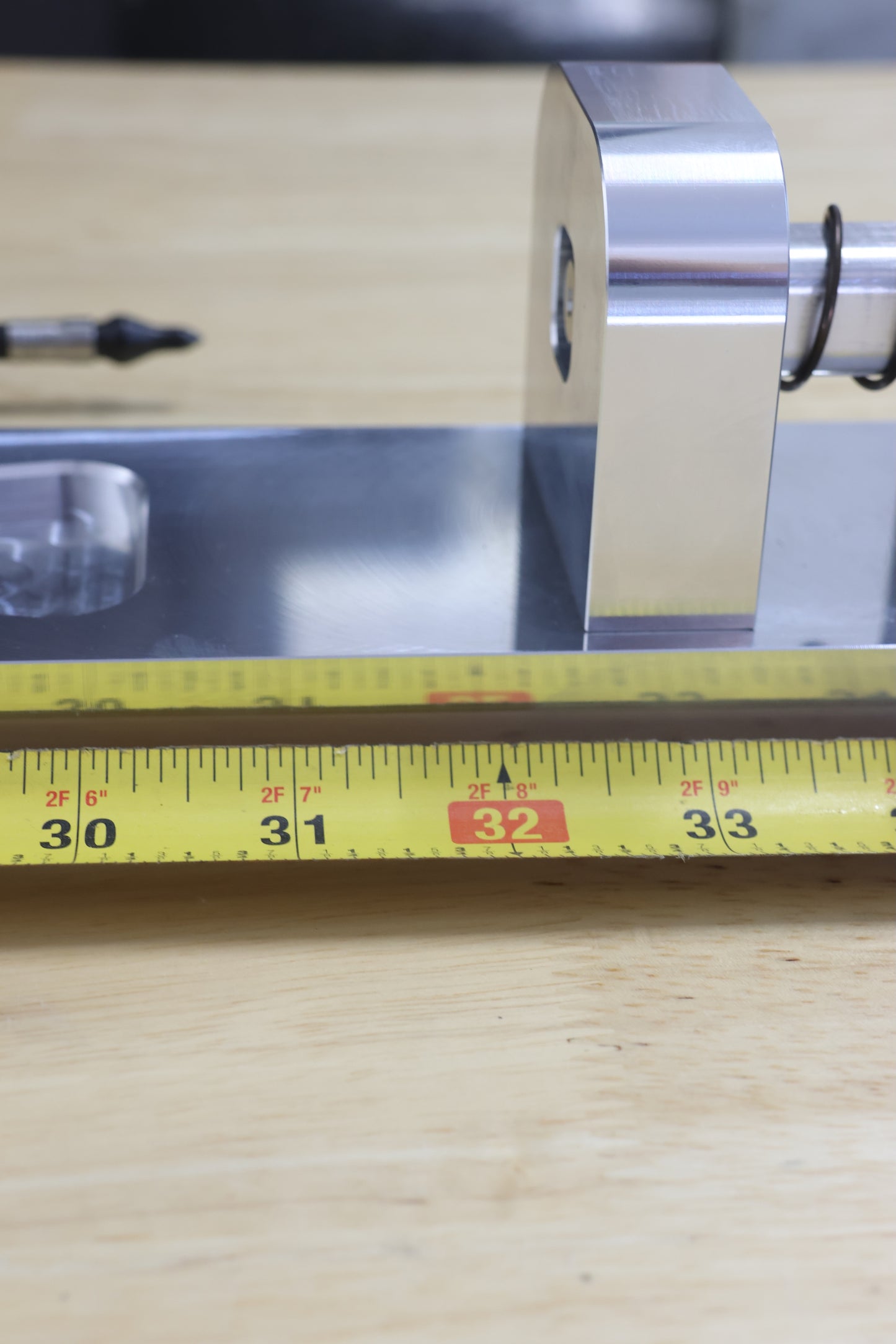

Note: Fits Arrows lengths 26"- 32" from field point to field point.

Presses now have updated locating point in the Arrow Press now accommodates a much wider range of field points—no special point is required, as most standard field points will work. Additional product updates include the use of Delrin in high-wear areas to enhance durability and function. As a result, the final product may differ slightly from the photos.

The Trif Arrow Press uses a patented indexing system that replicates the dynamic forces an arrow experiences at the moment of release, allowing archers to align each shaft precisely to the same axis of flex. Spared no expense and Machined from aerospace-grade 6061-T6 aluminum, every unit is proudly engineered and manufactured in Arizona.

By identifying the natural weak side of each shaft under a precise simulated load, the Trif Arrow Press ensures consistent arrow flight across your entire quiver. It minimizes inconsistencies caused by around shaft spine variation, making sure every arrow bends in the same direction—relative to one another—for unmatched uniformity. It's an essential tool for archers who demand precision, consistency, and confidence in every shot.

But remember—your arrows will only shoot as well as you do.

Instructions-

1. Set-up press

- Place the Trif Arrow Press on a stable, level surface.

- Using a 5/16 Allen key, ensure the dovetail is adjusted to accommodate your Arrow.

2. Arrow prep

– Once the arrow is cut to its finished length, ensure both ends are clean and square.

– Wrap a small strip of masking tape around the center section of the shaft, making sure it fully encircles the Arrow.

– Install an outsert and field point on both ends of the arrow.

3. Pressing Arrow

– Open the arrow press to accommodate the arrow, then insert the field points into the two locating holes.

– Slowly turn the handle until the arrow is fully seated in the locating holes. Then continue pressing until approximately 2 inches of deflection is visible at the center of the shaft.

- Observe the direction in which the Arrow bends—the bend will always indicate the weak side of the shaft.

4. Marking Tape

- While the arrow is flexed, mark the inside of the bend (the weak side) on the masking tape using a marker.

– With tension fully released, rotate the arrow and repeat the bending process several times. For each press, accurately mark the direction of deflection.

- It’s good practice, once the weak side is identified, to rotate the field points and inserts during pressing to confirm that the arrow continues to flex in the same direction. This helps rule out any variations caused by components other than the arrow itself.

5. Marking Arrow

– Before removing the masking tape, use a light-colored paint marker to draw a line—aligned as closely as possible with the dots on the tape—along the nock-side of the arrow shaft.

- Once the paint mark is dry, peel off the masking tape—your shaft now has a clean, permanent indexing mark.

6. Repeat for all Arrows

- Repeat the process exactly for each arrow in your batch to ensure consistent indexing.

7. Baseline for Bow tuning

-After indexing your Arrows with the Trif Arrow Press, you create a consistent, repeatable baseline for confident bow tuning. This ensures a tune from one Arrow transfers more accurately to the next and can be reverified anytime for long-term consistency.

Share